Composite foams: The sustainable solution for robust applications

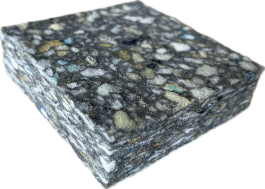

Composite foams are produced by using recycled foam residues in the form of flakes to create a flake composite foam. The product represents the classic recycling process for PU flexible foams.

The aim of the production process is to maintain the open cellularity and elasticity, the even distribution of the functionally appropriate additional materials in or on the cell structure and the integration of the solid partner materials into the foam matrix, while retaining the functionality.

Hanno composite foams combine the unique properties of PU foams with precisely controllable additional benefits and make a contribution to environmental protection.

On this page

Polyurethane (PU) composite foam

Characteristic properties

(depending on the application)

- recycled product

- Good sound absorption

- Good sound insulation

- weight-increasing

Product overview

Polyurethane (PU) composite foam