Study: Material effectiveness depending on the installation situation of windows and doors with regard to their suitability for passive houses

The BBS Institute of Prof. Dr.-Ing. H.-P. Leimer from Wolfenbüttel has carried out a comprehensive study on this on behalf of HANNO.

In a recently published study on the effects on employment and the need for training and qualifications in the field of energy-efficient building refurbishment, the Federal Environment Agency listed the following facts in the introduction: The building sector accounts for 40% of energy consumption in Germany. Appropriate measures could reduce this energy consumption by around 20% by 2020. However, the possibilities in the area of energy-efficient building refurbishment are far from exhausted, as only around 1/3 of the financially worthwhile savings potential in building refurbishment has been realised to date. The German government has therefore emphasised the energy-efficient renovation of buildings as one of its key areas of activity and has promised corresponding funding measures in the future. However, it is also important that the work is carried out by appropriately trained specialists.

This raises a key question: What scientific findings are there, for example, on how to seal window and door connection joints in a durable and energy-efficient manner? Until now, there has been a gap in the search for such scientific findings. The BBS Institute study set out to close this gap.

In order to have the following questions scientifically evaluated, HANNO commissioned the BBS Institute of Prof. Dr.-Ing. H.-P. Leimer from Wolfenbüttel:

Energy-optimised buildings require the optimisation or minimisation of thermal bridges. What about window installation in this context?

One of the key criteria is the air tightness of the building envelope. How does this air tightness behave during the permanent use of the building and during temperature change loads that act on a building and the joint?

Energy-optimised buildings should save energy in the long term. A permanently functional joint is therefore required for window installation. How does the joint behave under diffusion and convection loads over a long-term period?

In collaboration with the former head of HANNO-Anwendungstechnik Bau, Dipl.-Ing. (FH) Björn Kethorn, expert in heat and moisture-related building damage, Prof. Dr.-Ing. H.-P. Leimer and Mr Jan Schneider from the BBS Institute have developed a concept for this.

Energy assessment of building connection joints

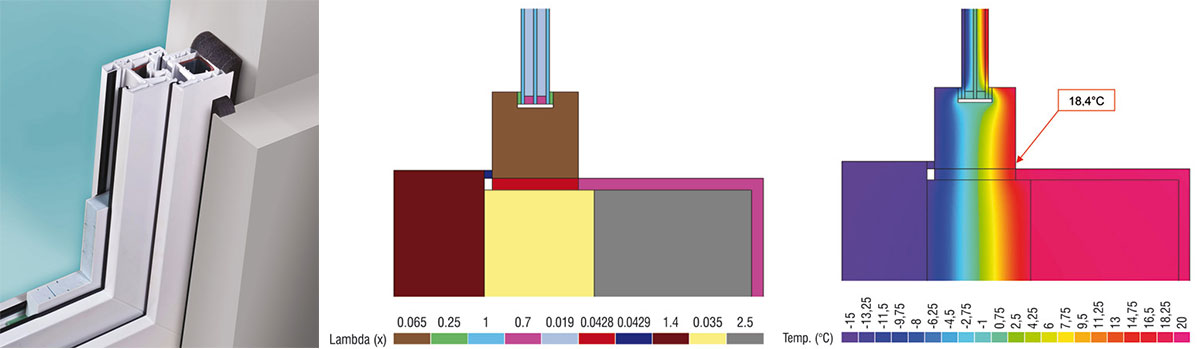

The ift Rosenheim guideline, "ift guideline WA-15/2: Passive house suitability of windows, external doors and façades" [2], in particular section 4.3, was used as the basis for the assessment by the BBS Institute and subsequently the mathematical verifications were carried out with various products of the Hanno 3-level joint sealing system.

In order to evaluate different constructions, two constructions were selected from Appendix 1 of ift Guideline WA-15/2 , one being a stop brickwork with clinker bricks and the other a monolithic brickwork with a thermal insulation composite system. These constructions were then each evaluated with several sealing systems and different installation positions of the building elements. The surface temperature Өsi, the temperature factor fRsi and the length-related heat transfer coefficient Ψi wereused as evaluation criteria.

The results show that, with good planning of the thermal bridge, the calculated losses can be almost completely eliminated in this way.

Influence of the thermal conductivity of the sealing products with the same construction

If the surface temperatures Өsi are used, a difference of up to 0.4°C can be seen here. For this reason, HANNO specifies the thermal conductivity for all its sealing materials. Even decimal places cause relevant differences. This is why, for example, the λ value outstanding for a multifunctional tape is given in full as 0.0428 W/(m*K) for Hannoband®-3E.

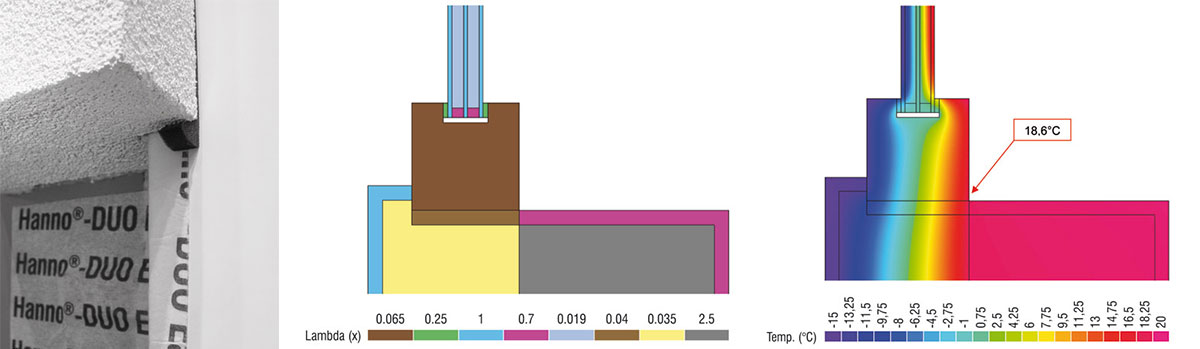

Influence of the installation position of the building elements depending on the construction

In the case of monolithic masonry with a thermal insulation composite system, the position can have a significant influence on the length-related thermal transmittance ψi, depending on the construction masonry. From an energy assessment perspective, it may make sense to place the building elements in the insulation level of the external thermal insulation composite system. Thermal conductivity is also a significant factor in this area, but here it is more important for the surrounding thermal insulation than for the sealing product.

Based on these findings, HANNO has developed a system with the product flashing tape Hanno®-DUO Easy, which on the one hand optimally fulfils the requirements for sealing and on the other hand does not place any restrictions on the surrounding thermal insulation materials.

Conclusion: All products in the Hanno® 3-level joint sealing system can be considered suitable for passive houses in terms of their thermal properties.

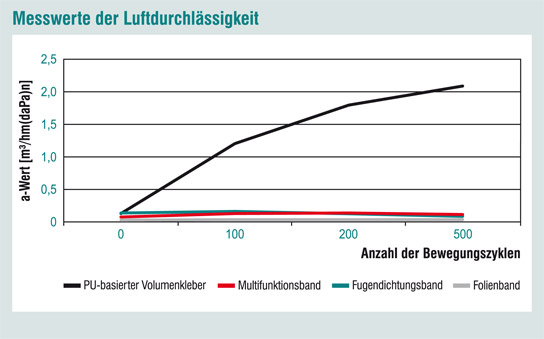

In part 2 of the study, the durable air tightness was analysed.

The following question was investigated here: How does this air tightness behave during the permanent use of buildings and the alternating temperature loads acting on a building and the connection joints of building elements?

In general, structural connection joints of windows must be made watertight and airtight to prevent moisture from penetrating the structure. Using a defined PVC window with a profile length of 2.18 m, the movements to be expected from the pure thermal expansion were determined and set at 3 mm per joint side. Based on this 3 mm joint movement, special test specimens were developed, built and fitted with 4 different sealing systems. The joint flankn of the test specimens are made of solid wood and sand-lime brick. Several test specimens of each sealing product were built in order to achieve a variance in the measured values.

Three different products were installed in the window joint for this purpose:

joint sealing tape, executed with Hannoband®-BG1 in the test.

Joint sealing tapes of stress group BG1 according to DIN 18542 as of 2009 only have to fulfil the requirements for the outer air tightness. However, the tape was also tested in order to determine how a diffusion-open product for the outer seal behaves with regard to air tightness in the event of joint movement.

multifunctional tape, tested with Hannoband®-3E.

Multifunctional joint sealing tapes are products for all three sealing levels of the window connection and are therefore also directly responsible for the air tightness of the joint.

Joint sealing film, here with flashing tape Hanno®-Duo Easy.

Film tapes are considered airtight per se. The main focus of the test here was to use a stretchable material and to install it "tightly", i.e. without the stretch reserve required for non-stretchable systems, and thus also to test the stretchable property.

PU-based volume adhesive, executed with the product of another market participant.

The test is intended to show how such products behave in real joint movements. As the measurements involved a test setup that deviated from the usual joint tests in accordance with EN 1026, the measured values could not be compared with the values from standardised tests, but a very good comparison could be made between the systems.

Results show clear differences in expanded joints

While there were only minor differences between the individual sealing products in the initial joint of 15 mm, the joint permeability coefficient was 10 times higher with the PU-based volume adhesive:

Conclusion: The proven systems fulfil the requirements without any problems. The products air tightness intended for the flashing tape Hanno®-Duo Easy and the multifunctional tape Hannoband®-3E can be used in construction without restriction.

The alternative system for airtight sealing cannot fulfil the movement requirements defined as normal in this test. It is not suitable as the sole, permanently airtight seal.

What impact does this effect have on the joint and its moisture balance?

To answer this question, a thermal-hygric building simulation calculation was carried out by the BBS Institute in Wolfenbüttel by Prof. Dr.-Ing.

Firstly, the systems were calculated with complete air tightness, i.e. with an a-value of 0.0, in order to see how the systems behave under pure diffusion loads and to obtain a reference. In the second step, the air permeability values of Part 2 of the study were also considered by extrapolating the behaviour of the connection joint over a period of 5 years.

This very complex approach was used to demonstrate the influence of the perpetual combination of diffusion and convection on the structural connection joint.

When considering the diffusion effects alone and the theoretical approach of 100% air tightness, as expected, no harmful accumulation of moisture in the construction was detected in any of the systems.

If the values for convection are now added, the systems with Hannoband®-BG1, multifunctional tape Hannoband®-3E and flashing tape Hanno®-DUO EASY show excellent values and the material moisture in the joint even decreases compared to the initial value. The sealing variant on PU-based volume adhesive considered in the study, on the other hand, caused leaks that lead to an accumulation of moisture in the joint over the years of use. This solution can therefore not be described as permanent and is therefore not an alternative for airtight sealing.